End grain cutting board vs edge grain cutting board: which product is good for sellers?

End grain cutting board vs edge grain cutting board: which product is good for sellers?

For a long time, wooden cutting board products have always been loved by home cooks, and professional chefs and are one of the extremely potential export products. But have the sellers had the best choice for themselves in choosing between 2 types of wood chips: end grain and edge grain

I. End grain vs edge grain

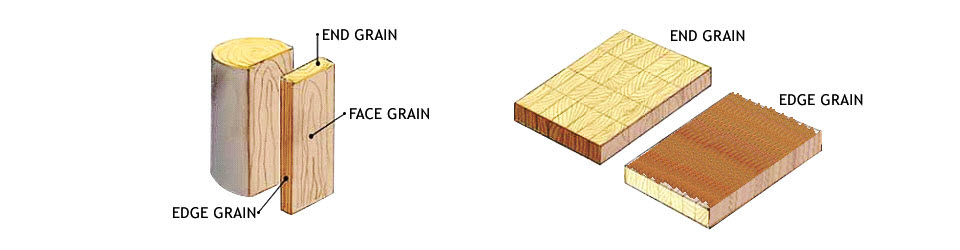

In cutting board-making techniques, there are many types of techniques developed to serve the needs of customers in the market, in which, the 2 most common techniques can be mentioned as end grain and edge grain cutting. This name is named after the method of wood that is applied in the process of making cutting boards.

End grain vs Edge grain

End grain Wooden cutting board

An end grain cutting board is a type of cutting board that is processed based on the technique of turning the wood grain edge grain so that on the surface of the finished product, we can see the fifth ring of the wood trunk on the cross-section.

The production and production technique of end grain cutting board products is a step forward in both functionality and aesthetics. Compared to the conventional way of producing cutting boards, the production according to this technique is more expensive in terms of raw materials and necessary machines. The arrangement or combination of wood grains so that they are beautiful is also a matter of concern for the workshop, and the skill of the machinist also needs to have a guarantee factor, because this factor is the decisive factor for the quality of the cutting board.

In addition to the output product having an eye-catching appearance, the technique of making cutting boards end grain also brings durability to the product, when the wood grain is less hydrated, reduces scratches, and is easier to preserve. These factors have contributed to the cost of early cutting boards being much higher than the general ground. Not only that, but the bearing force from the knife of the end grain cutting board is also a feature that helps the knives used on the surface of this cutting board to be more durable than the edge grain cutting board when the contact surface creates a line perpendicular to the wood grain, the force from the knife is more evenly distributed, making the blade not worn out during the cutting process.

The disadvantage of this manufacturing technique is that the products have a production process that takes more time and money when the processing has to go through many steps from gluing, end grasping, grinding, and polishing more complicated than edge grain processing.

This cutting board-making technique is often applied to hardwoods such as oak, chestnuts, cherries, sandalwood, sandalwood, etc.

In particular, teak cutting boards produced according to this technique are popular in the North American market, by famous chefs or food bloggers. When looking for end grain cutting board products on e-commerce sites, the number of sales of a store that sells on the first page can be up to several thousand units a month, which is just new in the retail market. Large distribution enterprises also recognized the business potential of this cutting board, and gradually, the technique of making Teak cutting boards has come to many manufacturing enterprises in many different countries.

End grain cutting board

Edge grain cutting board

This is one of the techniques for making cutting boards that has been around for a long time and is often used based on cutting boards made from a single type of wood. Simply put, the wood grain is placed on edge grain, and connected in a single direction, the production process based on this technique is not too complicated, but only relies on the edge grain joining of wooden bars. This makes the production process of edge-grain cutting boards much less expensive and complicated. The most decisive factor for product cost is the material of the wood used in production.

The biggest advantage of edge grain cutting boards is that the price of the finished product is more accessible to buyers, and the designs of edge grain cutting boards have also been familiar to most consumers for many years. Therefore, in the retail market, these products are more profitable thanks to being familiar with many generations of consumers.

Edge grain cutting board

In terms of functionality, edge grain cutting boards more or less have some disadvantages in terms of preservation and hydration. It can be understood that the force of the blade on the wood grain is right between the wood grain, and this makes the water go deeper between the wood grain than the tip, leading to the cutting board sucking more water. Over time, traces of blade lines will also appear on the cutting board, and users need to regularly maintain the cutting board by gently cleaning, drying with a towel, leaving the cutting board in a cool place, avoiding close contact with harsh cleaning chemicals, oiling the cutting board at least once every 3-6 months with a clean cloth.

The most important thing that sellers need to consider, is to find themselves a reputable and quality wooden cutting board manufacturer. No matter what group of products you are looking for, whether it is an edge grain cutting board or a floppy cutting board, the quality of the manufacturer for large orders is always a top priority.

II. Advantages of wooden cutting boards

- Better blade protection

Wood is often known for its many advantages such as aesthetics, woodiness, color, and especially the ability to protect the blade. After a long time of use, the experience on the wooden cutting board still brings a much better feeling when having an impulse-absorbing surface that protects all blade materials.

- Better antibacterial

There is a myth about wooden cutting boards that this type of cutting board increases the ability of bacteria when cutting and slicing materials related to meat and fish, that these cuts will create lines on the surface of the cutting board, leading to the accumulation of bacteria. But this is not related to the material of the cutting board, on the contrary, some cutting boards also can self-antibacterial thanks to the natural essential oils in the cutting board. A special feature of wooden cutting boards is that they can be easily cleaned by using baking soda and lemon after using to cut slices, rinse gently with warm water, dry, and store in a cool, dry place.

- Microplastic restriction

According to the WHO, the average adult body's body can contain 20 pieces of microplastics. In the process of eating animals and plants such as seafood, humans can also tolerate microplastics, and this process can be even more serious if using unsafe plastic cutting boards because microplastics can invade deep into food and enter the body.

III. Find a reputable manufacturer for your cutting board

Although the production of cutting boards does not require too complicated techniques, sellers themselves are always worried about finding a reputable cutting board distributor because of the following standards:

- Transparency in the origin of raw materials

When producing wood-related products, sellers always look for reputable manufacturers, with clear information related to the origin of raw materials from wood, glue, and other information related to the additives used, because kitchen products such as cutting boards will have a direct impact on users who are guests goods in the retail market. Therefore, if the information related to raw materials and additives used in the grinding process is not safe, it is not necessary to take the last step for the product to reach the customer, but the product is not eligible to be on the sales shelf.

- Production techniques ensure quality and quantity

To be able to cooperate for a long time and develop together sustainably, both sellers and manufacturers-distributors need to have a long-term development plan, which is that the manufacturer needs to have enough factory size, machine quality, production techniques, processing processes, etc packing, shipping, and labor quality. If a unit has good product quality but cannot ensure the production quantity, the seller will also hesitate to nod to cooperation. But if the production scale is large, but the factory itself cannot ensure the quality of output, then the biggest loser is none other than the seller.

- Long-term prestige

Although the essence of a distributor is product quality, the fact that a business has a long-term foothold in the market is also a factor worth considering for businesses. When gaining prestige in decades, it is clear that the priority level of the business for the business will be much better. Along with that, documents related to quality certification, and export standards from reliable organizations are also big plus points in the eyes of customers.

- Related Manufacturing Experience

The selection of a supplier or manufacturer by a seller can be based on the factors of price, reputation, and related production experience. Sellers often prioritize looking for manufacturers with relevant production experience, such as kitchen furniture, wooden tray trays, bowls, chopsticks, forks, from wood, then the production of products such as cutting boards will also be more convenient. Of course, this is not a key factor, but it is a point worth noting for the seller. For example, handing over the entire product to a manufacturer who has no relevant production experience will be an extremely big risk.

- Export papers are transparent, meeting international standards.

In the process of doing business, especially distributing products to international markets, inspection documents are always a mandatory requirement. Sellers need to learn the relevant methods to get useful information for the export process.

IV. Where to Buy Wholesale wooden cutting boards and Direct Manufacturers

When looking for high-quality wood and Teak wooden cutting boards, choosing the right manufacturer is important. If you're interested in purchasing at wholesale prices with quality assurance, consider working directly with reputable coaster manufacturers.

Thanh Tung Thinh is one of the leading wood and Teak wooden cutting board manufacturers in Vietnam. With many years of experience in the industry, Thanh Tung Thinh is committed to providing customers with high-quality wood and Teak wooden cutting boards, featuring modern production processes and skilled craftsmen. Their products are made from selected natural wood combined with premium epoxy, ensuring durability, aesthetics, and environmental friendliness.

Advantages of Buying Wholesale at Thanh Tung Thinh

Competitive Pricing: Thanh Tùng Thịnh offers wood and Teak wooden cutting boards at highly competitive wholesale prices due to direct production at the factory. This allows our partners to get the best prices without any intermediaries.

High Quality: Every coaster product is thoroughly inspected before reaching customers, ensuring strict quality and aesthetic standards.

Diverse Designs: With constant creativity and innovation, we offer customers a wide range of unique wood and Teak wooden cutting board designs, suitable for all modern interior trends.

Consultation Support: We understand that each customer has unique requirements, so our professional consulting team is always ready to assist you in finding the most suitable product.

How to Order and Collaborate

Thanh Tùng Thịnh always welcomes new partners looking for long-term cooperation. You can contact us through our website or visit our production facility to view product samples. We also support international export services, making it easy for distant customers to access our products.

V. Conclusion

Choosing wood and Teak wooden cutting boards offers benefits in terms of aesthetics, durability, and protection. With the perfect combination of natural wood and epoxy, you'll have a product that is not only beautiful but also extremely useful in protecting table surfaces. In the top 10 hottest coasters today, wood and Teak wooden cutting boards are

Latest Posts

Exploring the Export Market for Wooden Wholesalers in Vietnam

Custom Wooden Boxes with Reliable Shipping to American and Australian Markets

Wholesale Wooden Boxes with Fast Shipping to the U.S. and Australia

6 ways to optimize the wooden cutting board

How to find a beautiful wooden jewelry box for a seller